Water Well Pumps & Equipment

The submersible well pump, pressure tank, variable speed controller (see constant pressure below) and related equipment provide the backbone of any water well system.

Installed down the well column, submersible pump quality is of critical importance. Although brass, cast iron and even plastic composite pumps are available, stainless steel is the industry standard.

However, all stainless steel pumps are not created equal. Many pumps claim stainless steel construction. In most cases, only the external sleeve and possibly the discharge are of stainless steel construction. Unfortunately, the internal components of a submersible pump are the most important parts, subject to the most wear and tear.

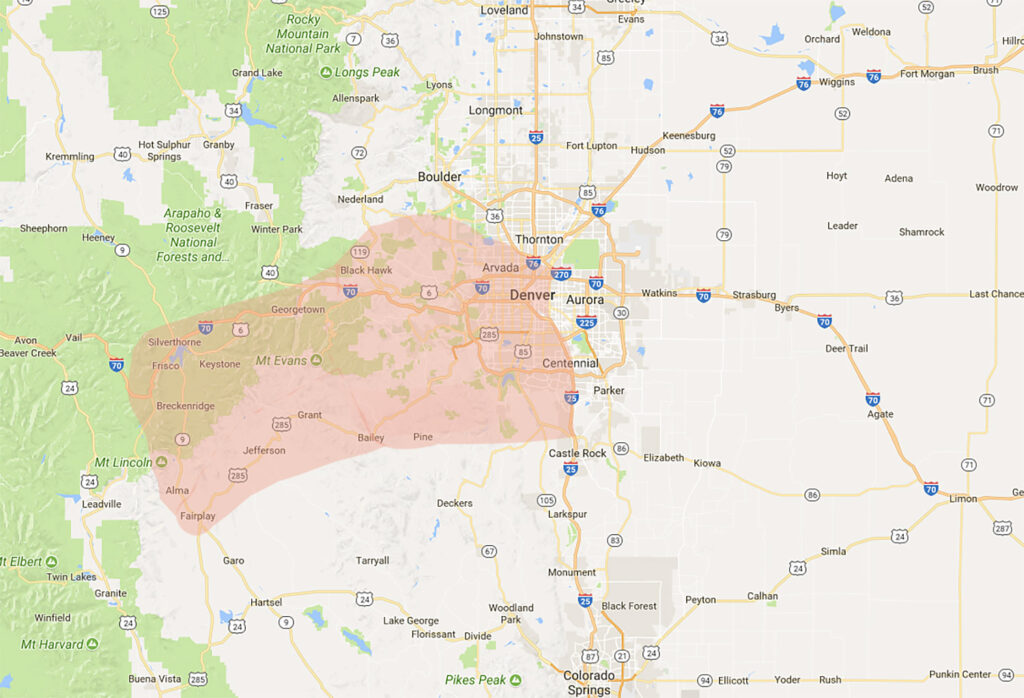

GeoWater Services is proud to be the exclusive distributor for Grundfos submersible pumps in our market areas. Grundfos standard submersible well pumps are the only submersible pumps with both external and internal stainless steel construction. Grundfos pumps offer high efficiency, superior heat resistance and durability, and excellent resistance to sand and other abrasives, all at pricing competitive with other pump lines. With a full 5 year manufacturer’s warranty, Grundfos submersible pumps offer best in class performance and support.

Standard submersible pumps systems are based upon a submersible pump installed in the well and controlled by a pressure tank and pressure switch (typically the big blue tank in the mechanical room).

When a faucet in the house is opened, the water in the pressure tank is used first. Once the pressure in the tanks drops to a specified level, the pressure switch turns on the fixed speed well pump to supplement water demand. When the faucet is closed, the well pump continues to run until a specified pressure is reach at the pressure tank, at which time the pressure switch turns the well pump off.

Advantages

- Generally lower replacement cost (existing systems only). In a failed pump situation, if the existing pressure tank and submersible wire are relatively new and of good quality, simply replacing the existing pump can be more cost effective.

- Familiarity. While not necessarily less complicated or more reliable, these systems are have been used for decades and better understood.

Disadvantages

- Pressure fluctuations. By working off of a pressure differential, the water pressure must drop to a specified level before the well pump turns on.

- Generally higher system cost in new construction or older systems. Constant pressure systems tend to be cheaper as the CP controller is more than offset by significantly reducing the pressure tank and electrical cable size (see below).

- Mechanical room space. The larger floor based pressure tank can be a problem in small mechanical rooms.

Constant pressure systems are based upon a variable speed submersible pump installed in the well controlled by an electronic controller. The electronic controller monitors water line pressure, adjusting the submersible pump run speed to deliver constant water pressure to the house. As such, many people refer to these systems as “city water pressure” systems.

Advantages

- Generally lower new installation cost. In a new construction or remodel situation, constant pressure systems tend to be cheaper. The CP controller is more than offset by significantly reducing the pressure tank and electrical cable size failed pump situation.

- Reduce / eliminate pressure fluctuations. Older systems, by working off of a pressure differential, the water pressure must drop a specified amount (typically 20psi) before the well pump turns on. Constant pressure systems work off of much smaller pressure differential (2-5psi), eliminating the noticeable pressure drop encountered in older systems.

- Technological advances. Constant pressure systems have built-in run-dry protection, voltage protection, and pump troubleshooting diagnostics.

- Mechanical room space. By eliminating the larger floor based pressure tank (replaced with much smaller wall mounted tank), can be a problem in small mechanical rooms.