Comparing Water Well Drilling Techniques: An Overview

When drilling a well, there are various methods that can be used. The best option will depend on the ground conditions and other factors.

Six Common Water Well Drilling Techniques

1. Air Rotary Drilling Method

The Air Rotary drilling method can be described as a double-edged sword of drilling procedures. It resembles the down-the-hole hammer drilling system in terms of design and function but boasts an added cutting action through its air-driven hammer. This technique uses pressurized air as a circulation medium, which offers excellent drilling speed, especially in hard-rock formations. It’s an effective method for well construction albeit noisy, and more comprehensive air control is needed to get optimum results due to the inherent dust and air blow associated with it.

2. Bucket Auger Drilling Method

Primarily used on unconsolidated material, the Bucket Auger drilling method is a go-to pick when constructing large-diameter boreholes ranging from 24 inches to 48 inches. This technique thrives in soils that don’t require casing until well completion, making it ideal for shallow wells. While it’s economical and adaptable to different geological formations, it struggles with hard rock or gravel pack formations, risking drilling mud contamination by shallow ground water.

3. Cable Tool Drilling Method

Classified as one of the oldest cutting actions utilized in the drilling industry, the Cable Tool drilling method—also known as churn drilling or percussion drilling—stands the test of time. This method works best where the formation is soft and relatively loose. It carries a reputation for reliability, however, the drilling speed can be slower as compared to other methods.

4. Down-the-hole Drilling Method

Distinctive for its rotary-percussive cutting action via the use of a button bit, the Down-the-hole drilling method leaves an imprint in any driller’s repertoire. This method excels in hard rock formations, as the hammer-effect directly administered on the drill bit facilitates faster penetration rates with less energy loss. It’s a testament to power and precision, even though the drilling cost could be relatively higher.

5. Reverse Circulation Drilling Method

The Reverse Circulation Drilling method is notable for its large rig size and requirement for a significant site footprint for both the rig and a machine-dug settling pit. This technique—although more complex—offers a range of benefits that include greater drilling depths, lesser risk of hole collapse, and reduced environmental impact. However, it requires more logistics in terms of machinery and water usage, which might increase the operation cost.

6. Mud Rotary Drilling Method

Emblematic of a closed-loop system, the Mud Rotary Drilling method involves constant recirculation of cleaned mud back down the borehole. This method functions well on unconsolidated and consolidated formations, allowing for quick, efficient drilling. Although it requires a careful choice and management of drilling fluids which sometimes might complicate the process.

In conclusion, the best water well drilling method often boils down to the specific ground conditions and factors pertinent to the drilling site. Each approach comes with a unique set of merits and limitations, underlining the importance of methodical planning and consideration before commencement of drilling.

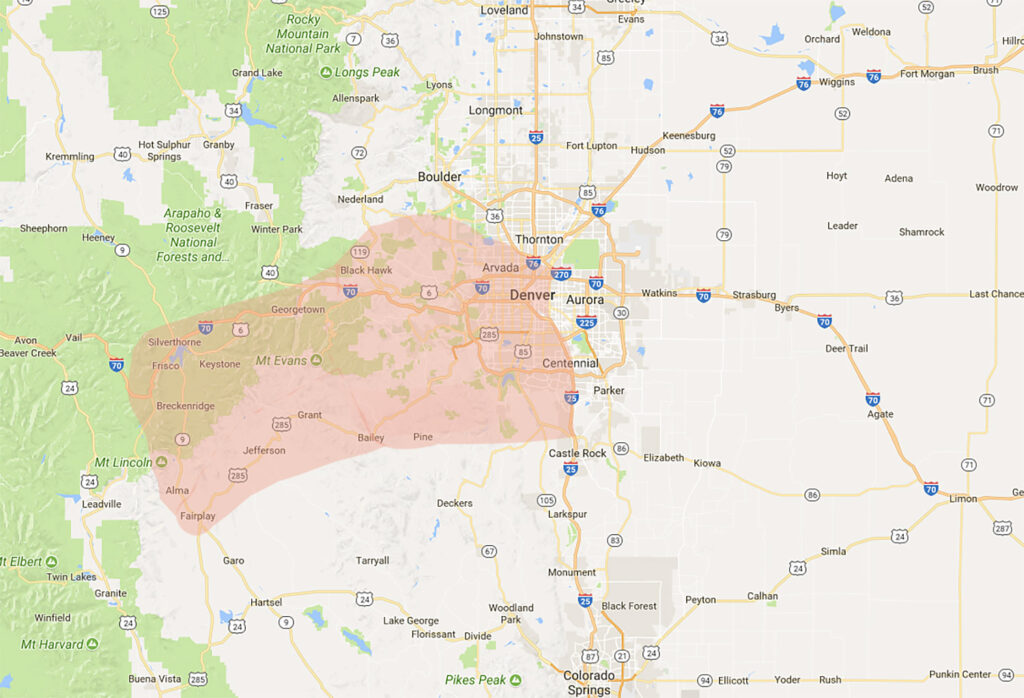

Contact Us to learn more about water well drilling. We proudly serve the Colorado Mountain Communities, Denver Metro Area, and Colorado Front Range.